Accessing Source-to-Pay Value Through Technology

New technologies have gone a long way in helping to streamline the Source-to-Pay (S2P) process, creating competitive edge for companies that successfully take advantage of it. Effective S2P technology can improve the customer experience, increase overall operating time, reduce the cost of goods sold, and streamline process operator efficiency. Although S2P best practices are generally consistent across industries, each company should craft its own tailored strategy using appropriate supporting technology. The COVID-19 crisis makes S2P and other high-return systems more important than ever, as businesses struggle to maintain profitability amid unprecedented revenue declines.

Here are a few things for companies to keep in mind as they prepare to use technology to maximize S2P value.

The use of three-way matching between purchase orders, goods received, and vendor invoices replaces the invoice approval process, effectively automating initial invoice review.

S2P technology provides value in many ways

Common S2P systems incorporate digital supplier qualification and requests for quotes facilitate consistent, controlled sourcing events. After awarding business to suppliers, the goods or services can be automatically added to purchasing catalogs for efficient digital purchase order (PO) creation. Digital POs enable sourcing and procurement policies including supplier selection, pricing, and management approvals needed before transmission to the supplier. POs prevent unneeded or incorrect costs and enable visibility into the committed spend against budgets to manage employee and manager performance. These systems can control certain kinds of purchases during disruptions like COVID-19 or operations changes to control cost or inbound shipment volume. The goods receipt process then allows consumers of purchases to validate supplier fulfillment. This can significantly reduce overpayments due to supplier invoicing errors and ensure high inventory accuracy. Additionally, the use of three-way matching between purchase orders, goods received, and vendor invoices replaces the invoice approval process, effectively automating initial invoice review. These best practices ensure supplies are purchased from preferred vendors and invoices are paid at negotiated rates with minimal AP input. Line-level invoice processing facilitates advanced analytics to rationalize the supplier base, item master list, and more accurate cost allocation. This rationalization will yield the most financial benefit of S2P technology implementation for most companies.

While many companies benefit from a supplementary S2P system, a company’s existing ERP might be enough

Many Enterprise Resource Planning (ERP) systems incorporate some relevant functionality contained in S2P systems like item catalogs, digital purchase orders, timekeeping, and inventory tracking. Low complexity businesses with few vendors, purchase orders, timesheets, expense reports, and invoice volumes often do well with popular mid-market ERPs. Some companies with significant physical assets like plants and equipment elect to use an Enterprise Asset Management (EAM) system to execute S2P processes with robust cost-tracking for specific assets and predictive maintenance. These solutions are especially prevalent in the energy, manufacturing, and distribution industries. Often, a supplementary S2P system is added to an existing ERP instead of transitioning to a new ERP since ERP implementations often cost much more.

Not all ERPs are created equal

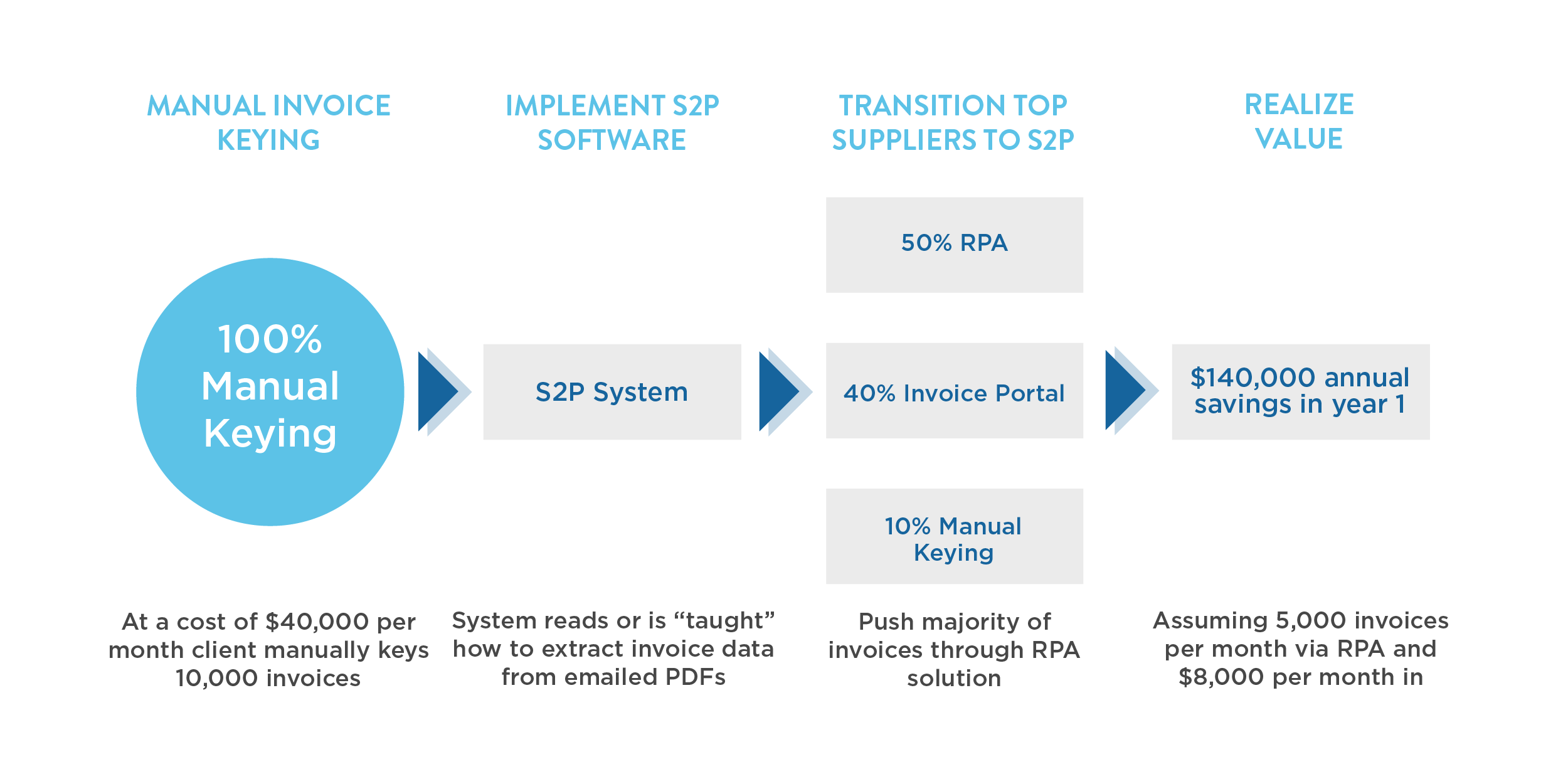

As volumes grow, legacy systems may not be equipped to efficiently scale. Inefficient manual sourcing, purchasing, and accounts payable—which work well for a small supplier base and low purchasing transactions—will require costly increased staffing levels and increasingly difficult process controls as the business grows. Many newer systems address these challenges. One area of significant recent evolution is invoice processing. Manual invoice entry and review is costly. The latest ERP and S2P solutions leverage vendor invoice entry portals and automated keying of invoices using Robotic Process Automation (RPA), which inputs invoice data. The image below demonstrates how these solutions reduce AP operations costs. Often less sophisticated ERPs can be enhanced with simple integrated application to manage the entire S2P process. S2P systems can provide deeper functionality than most ERPs for sourcing, procurement, timekeeping, expense management, and inventory.

Don’t forget about indirect spend

Companies often omit indirect spend from ERPs due to relatively high purchase transaction costs. For example, it doesn’t make sense to incur $15 of transaction cost to purchase $11 of office supplies. In these situations, companies will integrate a user-friendly S2P system into their ERP to reduce transaction cost and complexity. Other options include purchasing cards (P Cards) or travel and expense cards, which minimize purchasing transaction costs without reducing cost center visibility. There are numerous expense management systems to support this process with ample ERP integration options. These solutions can reduce purchase transaction time and costs by 30 percent or more.

Some S2P systems offer advanced functionality for robust contracting

Many mid-market ERPs have limited capacity in supporting tiered volume pricing, or parent and child contract relationships. In this situation, one option would be to use the contract management portion of an S2P or P2P system to guide and execute the sourcing process to realize the valuable benefits of hard-fought contracting wins.

It’s important for a company to understand whether it truly needs new S2P technology, how it will be used and the likely return on investment. Companies should start by assessing their specific goals, such as increasing purchase order-backed spend or lowering invoice processing costs. If these metrics are unavailable or difficult to influence, it may be time to revisit the S2P process design. S2P technology functionality architecture should be reviewed with S2P and technology process owners periodically to ensure current systems support these digital best practices.