Three Critical Steps for a Successful ERP Transformation Project

If you search “ERP implementation failures” online, you will inevitably find countless horror stories that are sure to keep any executive up at night. Not only will you see articles on the associated business disruption due to the required involvement of key subject matter experts, but also a look at real bottom line business impacts. One of the most well-known ERP implementation failures occurred at renowned chocolate manufacturer Hershey’s, which resulted in the inability to process $100 million of orders during the fall holiday season, fueling a 19 percent drop in quarterly profit and a corresponding 8 percent decline in stock price.

While there are indeed many stories of ERP implementations gone awry, it is possible to set your company up for success when undergoing a transformation project. By optimizing business processes first, leveraging standard functionality of the selected ERP, and focusing on user involvement and training throughout the implementation, companies can successfully implement a robust ERP system to reduce manual processes, increase real-time data availability and drive a substantial return on investment.

Build the right foundation

When embarking on an ERP implementation, it’s crucial for a company treat the project as an opportunity to identify and correct any underlying issues that likely contributed to the decision to invest in a new ERP software in the first place. A common reason for implementing a new ERP is the superior functionality of the new system but there are almost always process inefficiencies and inconsistencies that underlie the existing ERP. These inconsistencies will translate to user frustration, poor adoption and the appearance that the system isn’t working or configured appropriately; in reality, a new best-in-class ERP will exhibit the same shortcomings when built on top of inefficient business processes or replicating the same design to the new system .

The following steps demonstrate how to assess and optimize current state business processes as well as prepare the foundation for the configuration phase of the transformation:

- Hold future state design workshops across all major end-to-end business processes

- Rationalize the chart of accounts and align reporting requirements with ERP segments

- Develop a robust business requirements design document to serve as the blueprint for the configuration phase

- Create a task-level implementation project plan

- Build a forward-looking roadmap to incorporate other opportunities to leverage other technology applications for a complete solution

Often, clients view ERP implementations as a technology or IT effort, which can lead to a suboptimal system with an unrealized return. The approach outlined above will also greatly diminish the need to bring in additional consulting resources in the near future to optimize existing configuration or even worse, reimplement the ERP down the road.

Leverage standard processes

Many process leaders or participants believe some aspect of their operations merits an exemption to the best practices embedded within an ERP package. Although there may occasionally be a circumstance requiring a custom configuration, the benefit derived from incorporating the customization is likely to be less than the cost of implementing it. Frequently, decisionmakers fail to factor in the total costs associated with each customization, such as design, script implementation, testing, training, and maintenance. Some customizations will have to be maintained perpetually through ERP upgrades, as new changes in software versions can break these customizations. This can lead to ongoing disruption and consulting fees in order to test each upgrade release and potentially reconfigure the customization to work with the upgraded ERP. Additionally, with forward thinking cloud ERP solutions, there are apps designed to enhance core ERP systems in order to avoid custom solutions.

Due to the costs of customization, the project team should challenge whether customization is truly needed or merely the habits of past behavior. If there is indeed a need for customization, and an app does not meet the requirements, a proof of concept for the customization should be reviewed. From there, the team must analyze the cost benefit of the custom solution, estimating all previously described costs compared to impact of adjusting the existing business process to align with the process embedded within the ERP. This business case should then be presented to the internal steering committee to decide on the appropriate path forward for the implementation.

Train, train, train and involve key users

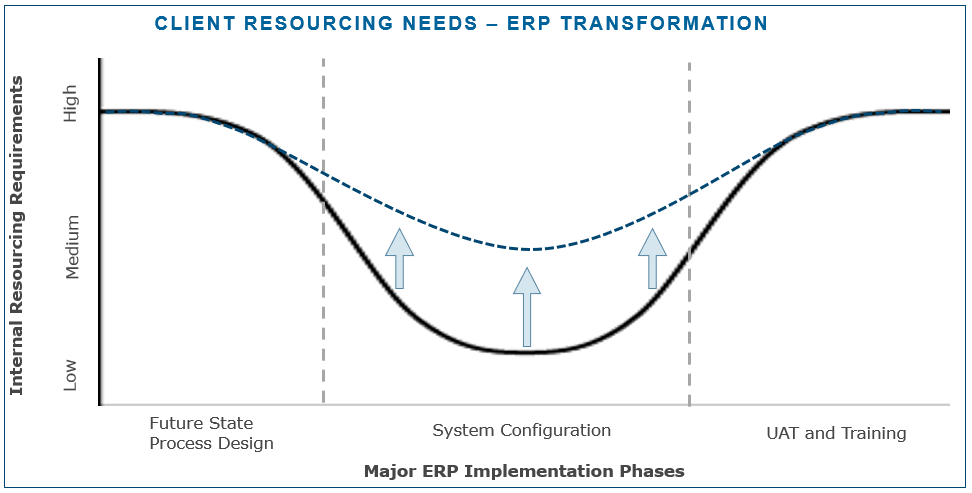

While engaging in any transformative initiative, it is important that day-to-day operations continue apace. However, because a company will likely engage a third-party consulting firm to design and implement the ERP, this should not be misconstrued as internal resources having minimal involvement in the ERP transformation. When companies are determining the amount of internal resources working on the project, they should prepare for an inverted bell curve with the level of involvement being highest during the design and testing phases and lower during the configuration phase. See the image below for more detail.

While the configuration phase traditionally requires fewer internal resources than the design, testing, and training phases, the more time spent by key internal process leads and participants during configuration will allow the users to become more familiar throughout the configuration (as depicted with arrows in the image). This will ultimately allow key users to be better equipped to get the most out of the ERP and troubleshoot small issues, creating a self-sustaining team that works efficiently within this system and not against it.

During the system configuration phase, the internal team should be involved in process walkthrough sessions, where each process is reviewed and informally tested by internal resources in the sandbox environment. This allows the system to be configured and tested in manageable pieces to ensure progress is made throughout the configuration and according to the design document completed in the future state process design phase.

Once configuration of the system is near completion, the key process participants will be heavily leveraged in the user acceptance testing and training phases of the project. The users must complete each testing script and document each perceived issue when executing against the scripts. Finally, a formal training curriculum should be developed to ensure all topics are verbally communicated and documented in the form of work instructions. If training is not completed and documented thoroughly, the slightest amount of turnover can lead to system knowledge leakage. A lack of training and documentation is one of the most frequently occurring reasons why an ERP system is either underutilized or results in failure.

ERP as a business transformation journey

An ERP implementation project can seem like a daunting endeavor that can cause disruption and anxiety amongst executives and employees. By approaching the initiative as a broader business transformation journey rather than a technology focused project—focusing on optimizing processes, leveraging best practices, using standard functionality, and engaging key resources—companies can obtain a process-aligned system that will help it to reach its business objectives.