Cultivating An Effective Strategy for Productivity and Growth

This article first appeared in California AG Network.

We have found that even elementary plans that include the three phases discussed here can lead to lower inventory carryover from season to season and thus lower storage costs.

Introduction

How much inventory did you have left over from the last harvest season? What about two seasons ago? For produce processors the answers to these questions can be a make or break proposition. Thin gross margins, fluctuating commodity prices and ever-increasing storage costs make proper inventory management critical to the overall profitability of your operation. As such, it is imperative to sell what you buy every year. In this article, we use a hypothetical company that sells a variety of products with two types of commodity availability. Some are available throughout the year, but one fresh product is only available for a short period of time. This causes a significant spike in production for a few months. It also demands a rigorous storage plan. We will discuss three key planning areas: Sales, Production, and Warehouse/Logistics. We will also discuss how they must all work together to achieve success.

Sales

The entire process begins, of course, with the sales forecast. It is the foundational key to effectively planning commodity purchases and production; projecting how much we need to meet this year’s demand and when we need it. The graph below shows a typical aggregate demand pattern depicting seasonal demand that is at its highest early in the calendar year.

As you can imagine, this type of demand presents some challenges. Because of our uneven production cycle we will have to produce and store a high percentage of our limited availability commodity.

The sales forecast needs to have a high degree of detail and should be at the customer item level by month in pounds. This detail should forecast at least 80% of expected demand for the coming year. This is critical information for the operations and finance teams as it helps in building the production schedule and timing of material purchases. It also allows finance to manage working capital and liquidity needs effectively. The impact of improper planning can be devastating.

It is important to understand that building a sales forecast is an iterative process. It is very unlikely that the sales team will have good demand visibility for the first pass which is based heavily on prior year demand and initial harvest indications from your grower network. Of note, we have found that using more than the previous year’s demand provides little value to the process. Consumer habits change rapidly. The second and third forecast passes continue to refine quantity and timing based on customer discussions and continued grower feedback. The third pass should be an accurate vision of the demand for the coming year. Finally, the forecast should be reviewed at a detailed level throughout the year to adjust for raw material issues and changes in demand and customer delivery timing.

Production

As we mentioned at the outset of this article, one of our production challenges is the limited time that our main product is available.

The implications are obvious. This spike pattern has significant implications to primary commodity purchasing decisions that include yield considerations and unforeseen demand. Other important issues to review include labor needs versus availability and the timing of other material purchases. The commodity will be coming in at a rapid rate.

Improper planning, on the other hand, will lead to chaos. For example, labor costs can quickly get out of control if needed packaging and other ingredients are not on site at the right times or machinery is not properly maintained during these intervals.

What is not so obvious in this pattern is the implication of poor planning for the non-peak production periods. Because the sales forecast indicates steady demand throughout the year, the timing of readily available commodities can have a significant impact on working capital needs. In most cases, purchasing can schedule material deliveries on a steady basis. We have found that having raw materials available to cover the next two months of customer demand is sufficient to maintain high customer service levels. It also leads to stronger supplier relationships when these consistent purchase patterns are maintained.

For both of these situations, a clean bill of materials (BOM) for each product is critical. This allows for proper raw material purchase planning and scheduling. It should also identify approved substitutions in case of primary raw material shortages. Further, BOM’s should be reviewed on a periodic basis to adjust for market changes.

Warehouse and logistics

Often overlooked in the planning process is the fact that storage and logistics can have a significant impact on the bottom line. Most companies do not have enough internal storage capacity to handle peak storage needs and, as such, must use a third party facility. Even for operations that possess sufficient internal storage, a year with extraordinarily high demand may result in no additional profit if storage is not managed correctly. To maximize the bottom line, companies should have a storage plan developed in conjunction with the sales forecast and production plan.

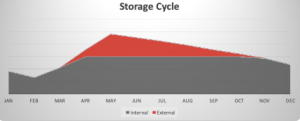

The graph below shows how a proper storage plan minimizes the use of third parties. The grey area represents Internal Storage, while the red area represents Third Party Storage.

The objective is to keep third party storage inside the red area. This means the production team must schedule for the items that will be sold immediately following the end of the harvest season. These are the items that are stored at a third party site and sold through in the shortest amount of time. A strategy like this one will minimize external storage and transportation costs.

Putting it all together

Coordinating these three strategies can be a daunting task. One of the ways to pull it all

together is with a well-defined annual operating plan or AOP. The AOP lays out the timing of all phases of the process while also clearly defining who is responsible for what activities. Depending on the size of operations, this may consist of several levels of detail.

And then there is the crop. No matter how well planned and detailed your strategies may be, harvest time will likely throw a wrench in the works. It decided to come in a bit early or grower yields were different from expected. There was no “knee high by the fourth of July.” Too much rain or not enough. Everyone has to be ready to adjust. The plan is in place. Only the timing has shifted.

We have found that even elementary plans that include the three phases discussed here can lead to lower inventory carryover from season to season and thus lower storage costs. It can also lead to significant reductions in borrowing needs, interest costs and operating expenses. What does your plan look like? Is it ready to take root?